Mobile Rotary Tunnel Kiln

We are the first and only one kiln company to develop and establish new structure mobile rotary tunnel kiln of freeing from fans at the kiln top, and this technology have obtained patent in China with 12 China national practical new-type patents. We are the first and the only one company of obtaining ISO9001, ISO14001 and OHSAS18001 certification in China’s wall materials firing kiln company by now.

We are the first and only one kiln company to develop and establish new structure mobile rotary tunnel kiln of freeing from fans at the kiln top, and this technology have obtained patent in China with 12 China national practical new-type patents. We are the first and the only one company of obtaining ISO9001, ISO14001 and OHSAS18001 certification in China’s wall materials firing kiln company by now.

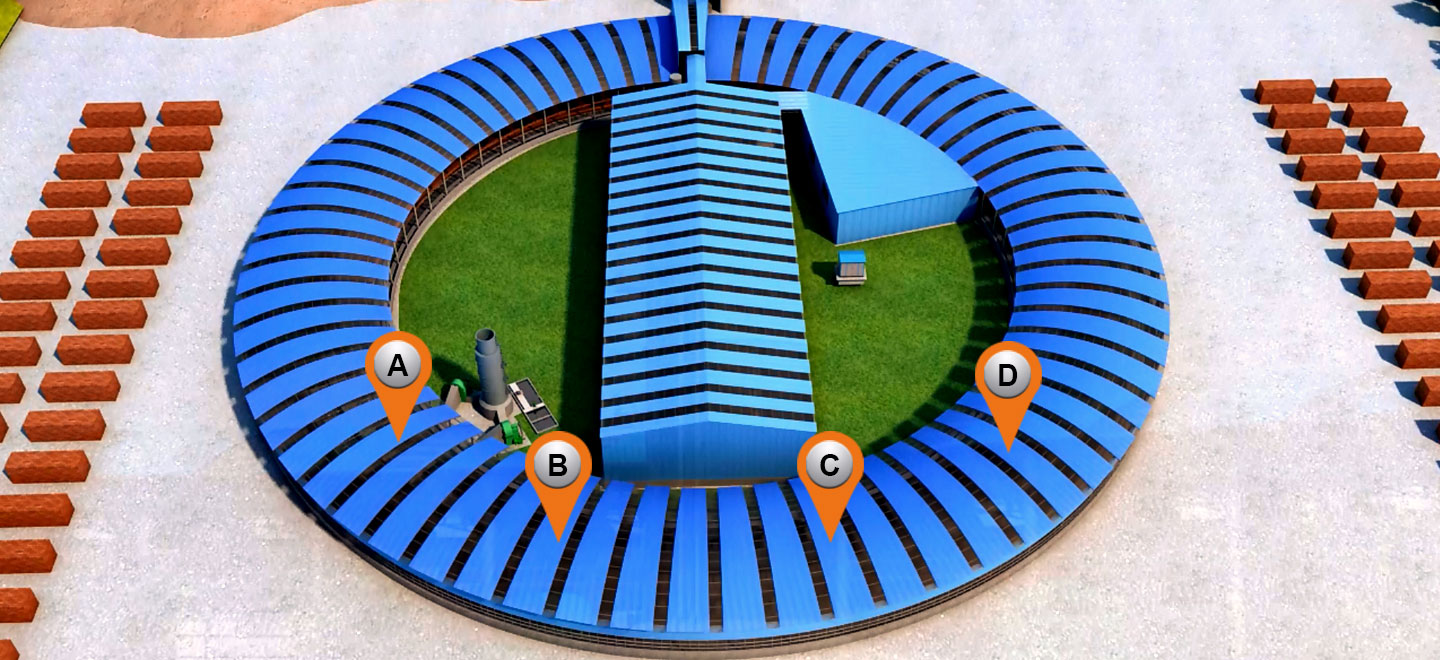

The structure of mobile rotary tunnel kiln body:

Our new structure mobile rotary tunnel kiln include kiln body, circular rails for the kiln move, circular flue connection to kiln body, desulfurizing fan (connection to one desulfurizer) connection to circular flue.

Based on the functions of each section, the mobile rotary tunnel kiln body is divided into 4 sections: drying and moisture eliminating section, preheating section, burning section, insulation and cooling section, and these 4 sections are connected together. The inner side wall and the top of the kiln body install moisture removing pipes and heat feeding pipes respectively.

The patent of our new structure mobile rotary tunnel kiln delete the fans of the kiln body, and take use of the desulfurizing fans to carry out the drying and burning. Freeing from fans of the kiln body, the kiln body don’t have any vibration, which prolong the service time of the kiln and the insulation materials. This new structure Mobile Rotary Tunnel Kiln also delete the check gate between drying section and burning section, which can send the heat to drying section from burning section directly and decrease the heat loss, then meet the requirements of environmental-friendly, energy-saving, high production capacity and less fuel and power consumption.

Characteristics of a new type of mobile tunnel kiln

- 01 The patent of our new structure mobile rotary tunnel kiln delete the fans of the kiln body, and take use of the desulfurizing fans to carry out the drying and burning.

- 02 Freeing from fans of the kiln body, the kiln body don’t have any vibration, which prolong the service time of the kiln and the insulation materials.

- 03This new structure Mobile Rotary Tunnel Kiln also delete the check gate between drying section and burning section, which can send the heat to drying section from burning section directly and decrease the heat loss, then meet the requirements of environmental-friendly, energy-saving, high production capacity and less fuel and power consumption.

- A Drying and moisture eliminating section

- B Preheating section

- C Burning section

- D insulation and cooling section

-

A

Drying and moisture eliminating section.

The kiln body moves forward, and the mud bricks go inside of drying and moisture eliminating section of the kiln, and dried by the recyclable flu gas of high temperature till the mud bricks temperature reach 200 ℃ or so.

-

B

Preheating section.

The bricks enter preheating section after dried to 200 ℃ or so at drying and moisture eliminating section, and reach 600 ℃ or so by the recyclable flu gas of high temperature coming from burning section.

-

C

Burning section.

The bricks are dried to 850-1050 ℃ in burning section till the bricks are fully burned.

-

D

Cooling section.

The bricks are cooled by the cold air, and the cold air are heating by the heat from burned bricks to change to be hot flu gas, most of which are recyclable for the drying medium of drying section.

Advantages of The mobile tunnel kiln:

-

01

Less investment and lower maintenance cost

Freeing from kiln car and no need construction materials (Clay bricks, sand, cement, etc.) for the kiln construction, the investment value and maintenance cost of mobile rotary kiln is lower than that of traditional tunnel kiln.

-

02

Energy saving and less coal consumption

The use of natural gas sintering technology has reduced the energy consumption of coal, which is of great significance for burning bricks and producing high-grade bricks in coal prohibited areas, and has also promoted emission reduction and environmental protection standards.

-

03

Fully automatic operation of the kiln

The kiln as a whole realizes one-button start-up intelligent control system, and the intelligent burning system automatically reads and calculates the sensor signals for temperature, humidity and pressure collected by each collection module of the kiln. By adjusting the frequency converter to control the air blowing volume intelligently and get designed burning temperature so that the blowing air, bricks and internal burning of the bricks can be optimally matched and the kiln operates at a higher efficiency to achieve the purpose of reducing internal burning consumption.

-

04

Fully automatic operation of the kiln

There is no fan on the top of the kiln body, and refractory insulation materials are used inside the kiln body, ensuring smooth operation of the kiln body. Under normal use, it can ensure that the kiln structure does not undergo major repairs for 10 years and the refractory insulation materials do not undergo major repairs for 5 years.

-

05

Environmental friendly and and no leakage of waste flu gas.

Dying by positive pressure at drying section, flu gas recyclable by micro-negative pressure, moisture eliminating by concentration, waste flu gas purifying by mobile type, which gurantee the clean working conditions and no additional corrosion on the steel structure of the workshop.

-

06

Simple structure and easy installation.

The kiln body adopt detachable steel structure of H steel and steel plate combination, and is easy for maintenance and installation.

-

07

Short kiln construction time.

The mobile rotary kiln can be finished within 4 months. All the kiln parts of the kiln is prefabricated in standardized and large-scale production in factory by uniform specifications, and installed on the plant site.

The advantages of mobile rotary tunnel kiln comparing with traditional tunnel kiln:

-

01

Bigger production capacity:

For traditional tunnel kiln, the biggest sectional width of tunnel kiln is 7.5 meters. For our mobile rotary tunnel kiln, the minimum sectional width is 7.2 meters, and the sectional width can be 7.2, 7.6, 8.6, 9.08, 10.8, 11.2, 12.98, 13.8, 16.38, 18.8 meters, and the length is 150-170 meters.

-

02

Short kiln construction time:

The mobile rotary kiln can be finished within 4 months. All the kiln parts of the kiln is prefabricated in standardized and large-scale production in factory by uniform specifications, and installed on the plant site. Traditional tunnel kiln can only be constructed with clay bricks and concrete by manual on the brick plant, and more than 6 months are needed for the kiln construction.

-

03

Less investment:

Freeing from kiln car and no need construction materials (Clay bricks, sand, cement, etc.) for the kiln construction, the investment value of mobile rotary kiln is lower than that of traditional tunnel kiln.

-

04

Operation directly freeing from baking:

The traditional tunnel kiln must be baked to evaporate a large amount of water brought in during the masonry process before it is put into operation. The mobile rotary tunnel kiln assembly does not contain moisture and can be put into operation directly after assembly freeing from baking.

-

05

Less maintenance cost and worker cost:

For traditional tunnel kiln, the kiln car maintenance cost is about 50000-100000 USD each year owing to the frequently repairing of kiln car. Moreover, many process are needed, say, ferry car, hydraulic step-by-step pusher, hydraulic pusher, drawing machine, etc., and about 7-10 workers are needed. For mobile rotary kiln, only 2 operators is ok, no need kiln car maintenance cost, no need overhauling for the kiln body within 10 years, and no need overhauling for the refractory insulation materials of the kiln within 5 years.

-

06

Avoiding bricks collapse:

For traditional tunnel kiln, the bricks are stacked on the kiln car and moves with the kiln car. It is easy to shake and collapse when the kiln car moves. For mobile rotary tunnel kiln, the bricks are stacked on the ground and not move, and the possibility of collapse is much smaller than that of the traditional tunnel kiln.

-

07

Less coal consumption:

For traditional tunnel kiln, the coal consumption is about 380-450 kcal/kg. For mobile rotary tunnel kiln, it is about 250-280 kcal/kg, and at least 100 kcal/kg can be saved.

Based on the weight of 3.5 KG per pcs brick, 350 Kcal (100 Kcal/kg×3.5 KG) are saved each brick. For the brick plant of 30 million pcs one year, 2100 tons coal (based on the caloric value of 5000 kcal/kg) can be saved each year.

-

08

More environmental friendly:

There is no fan on the top of the kiln, so the smoke will not be discharged unorganized; And, circular flue and drying room are seamlessly connected, which is energy-saving and environmentally friendly, and will not pollute the environment.